Battery and Energy

Battery and Energy

The battery and energy industry, particularly in the field of lithium-ion batteries, has been driven by the global expanding electric vehicle market and its related manufacturing activities. Another area pushing for better battery storage solutions is the growing call for emissions reduction.

A key challenge for battery manufacturers is the transfer of developments in materials, cell design and processes from the laboratory scale to production scale. This is due to many consecutive processing steps and the significant impact of material properties, electrode compositions and cell designs on these processes. The aim is to find the key relationships between the processes, quality and performance, as well as explore the impact of materials and processes on scale and cost. This requires an in-depth understanding of the individual production processes, their interactions and pilot-scale investigations into process parameter selection and prototype cell production.

At DKSH, we provide our customers with powerful intelligent technology systems to help improve process efficiency and overcome these production challenges while meeting the quality requirements.

Measurement Types

Particle Size Distribution

Particle size analysis in the range 0.01-3500 microns. For nanoparticle analysis see dedicated section.

Morphology

Morphological analysis of particles in the range 0.5-10000 microns (size, shape and transparency of particles). Integrated Raman chemical analysis with MDRS (Morphologically Directed Raman Spectroscopy).

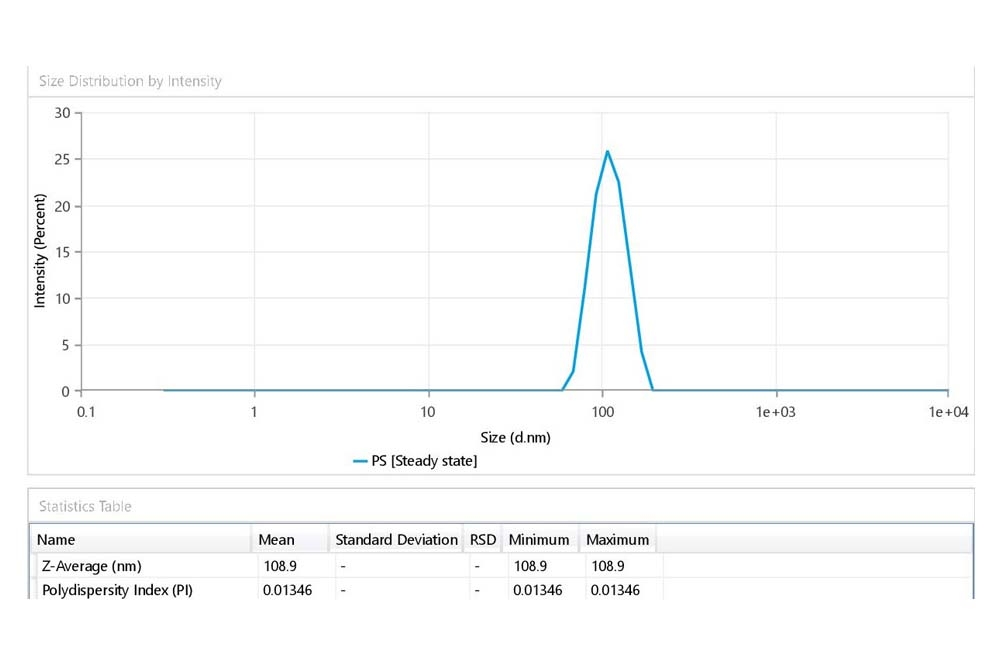

Nanoparticle Characterization

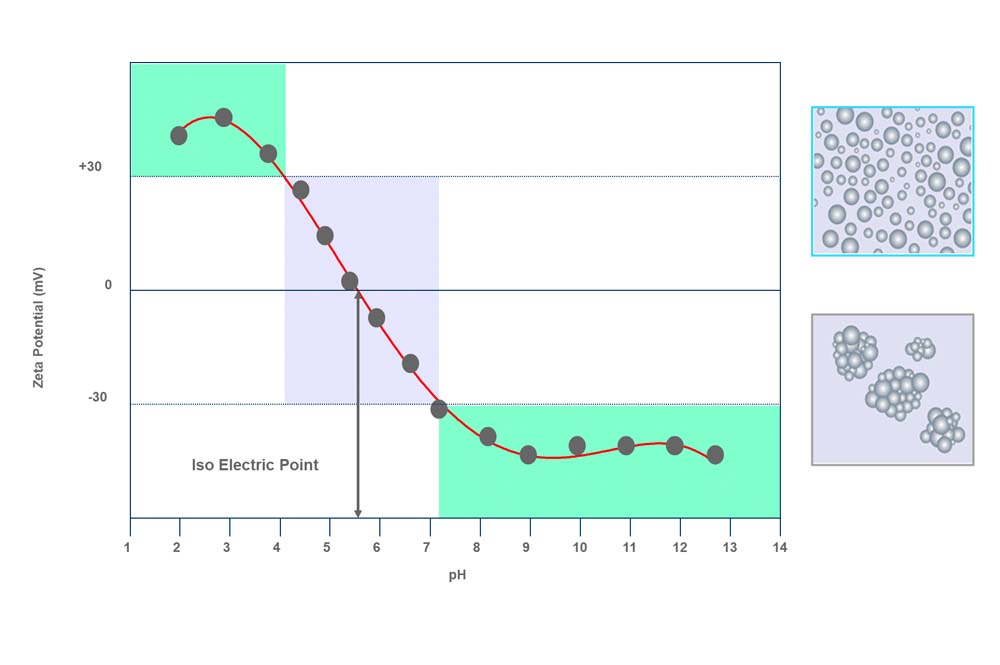

Size, concentration and zeta potential anlysis of nano-systems using light scattering techniques such as DLS, ELS and NTA techniques.

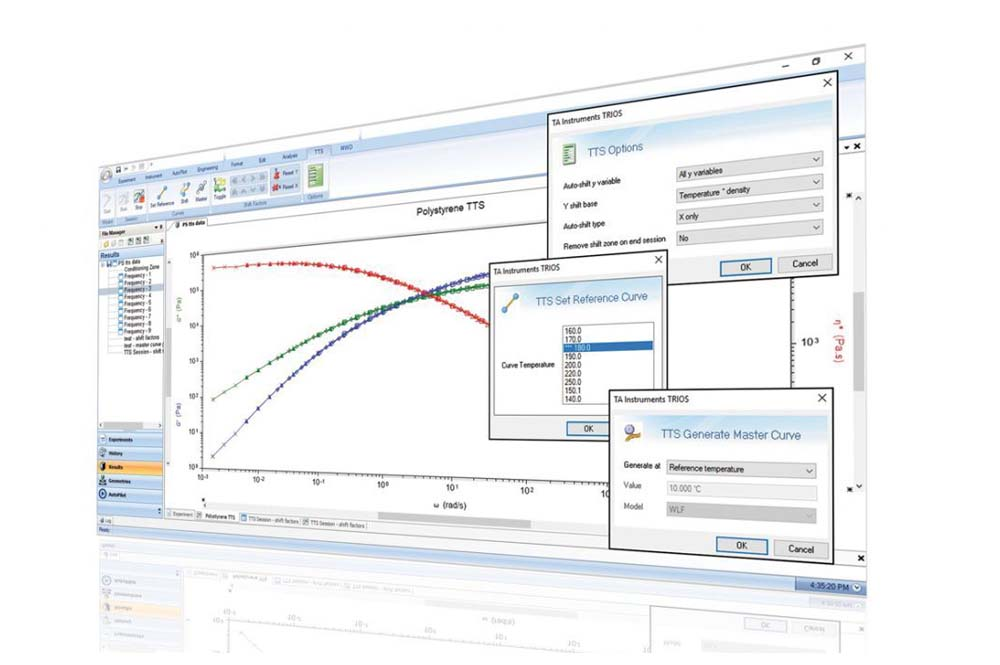

Rheology, Viscosity and Powder Flowability

Viscosity measurement and visco-elastic properties characterization of liquid dispersions, complex fluids and semi-solid materials.

Stability Analysis

Rapid and objective quantification of concentrated dispersion real stability using Multiple Light Scattering.

High Pressure Homogenizer

High pressure homogenizing technique to produce stable nanoemulsions, reduce particle size or molecular weight of polysaccharides, nanoencapsulation, de-agglomeration, etc.

Exosomes and EVs Characterization

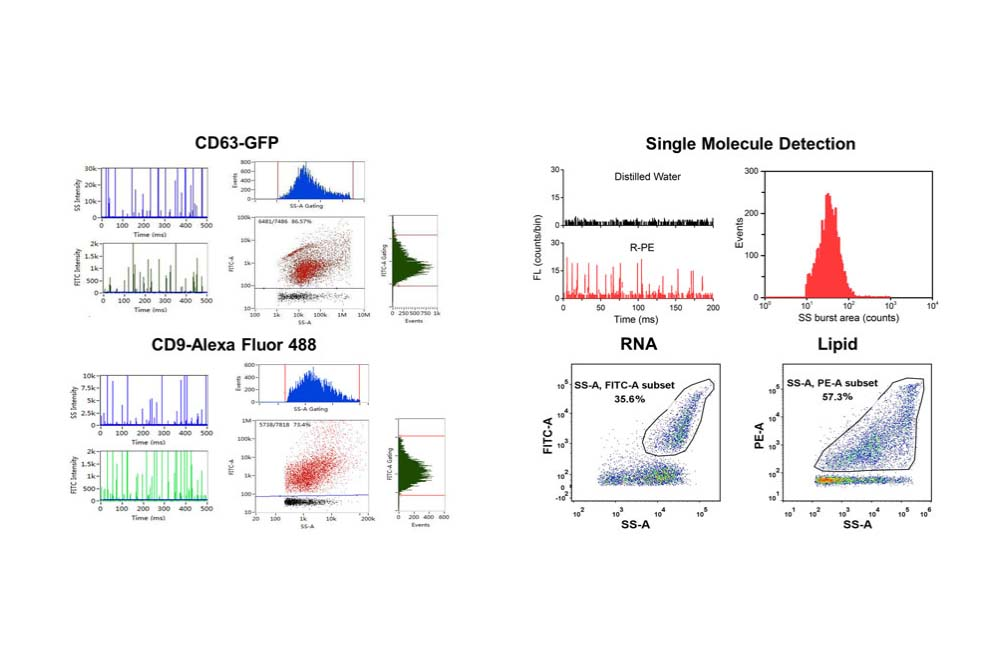

Multiparametric characterization of exosomes and EVs including Sizing, Concentration per size range, Count, Phenotyping, Cargo, Integrity, Purity, etc.

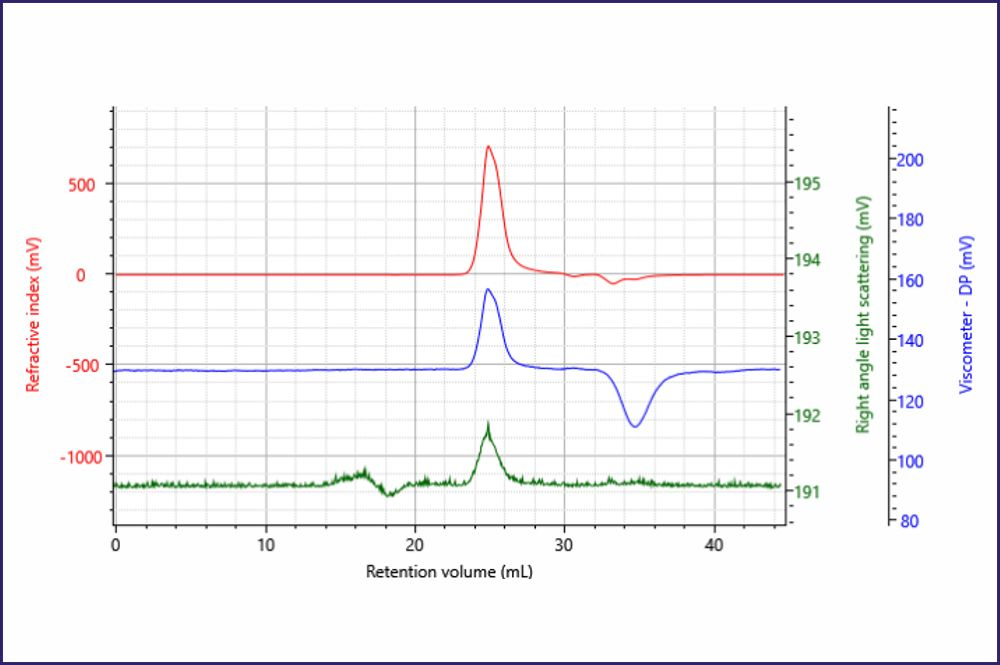

Protein Aggregate Analysis

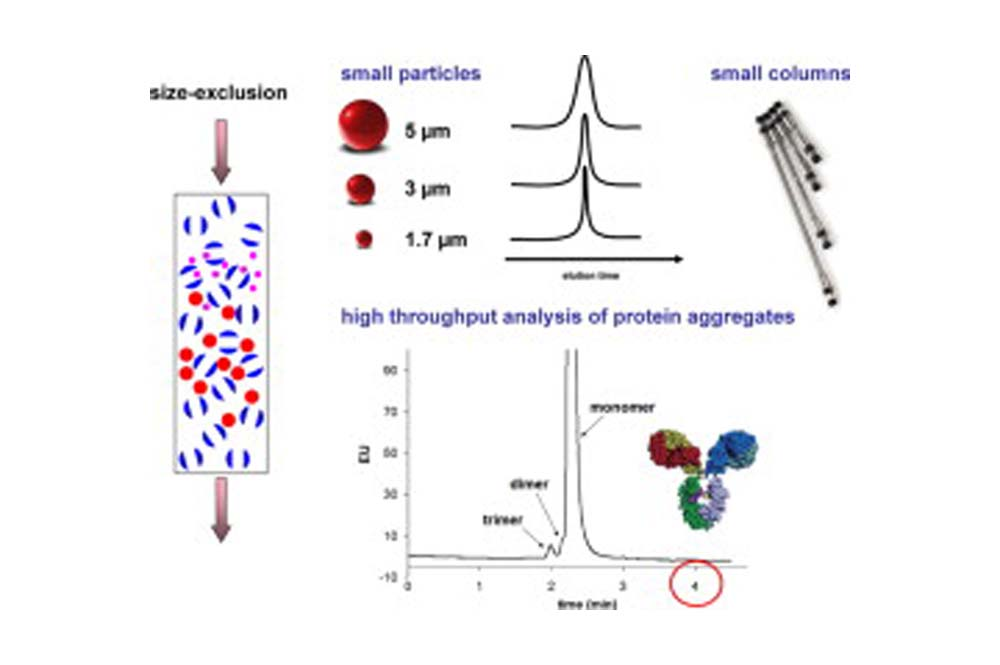

SEC is the standard method for protein aggregate analysis. The choice of pore size is related to the size of the molecule to be separated.

Subscribe now

Stay updated with the latest news and offers