Challenges in Polymer Nanocomposites Characterization

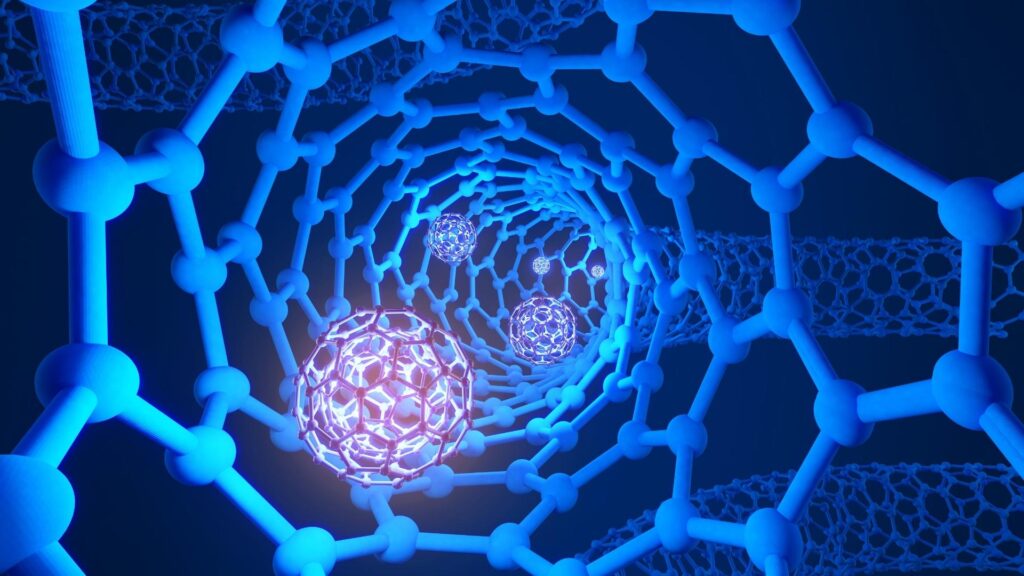

The intriguing perspective of imparting new physical properties and novel behaviors to a host polymer matrix through the simple addition of small amounts of nanoparticles is what makes polymer nanocomposites attractive.

Rather than aiming at the mere capitalization of the filler properties, the current trend is using nanoparticles as an active tool for manipulating the microstructure and, through it, the final performances of materials with phase-separated morphology, such as immiscible polymer blends.

The effects of filler adding can be a wide variety of property changes. Those are needed to be studied to predict final properties and evaluate suitability for specific purposes. Below are the properties that most nanocomposite polymers must be tested for.

DKSH provides a wide range of integrated and customized solutions including specialized analytical equipment and services in the fields of chemical analysis and material sciences. Reach out to us to find out how we can help with your business.

Sources:

- Effects of nanoparticles on the morphology of immiscible polymer blends – Challenges and opportunities

- Chapter 6 – Dynamic Mechanical Thermal Analysis of Polymer Nanocomposites

- Structure and rheology of nanocrystalline cellulose

- Microstructure, morphology and physicochemical properties of nanocomposites…

- Microstructural and morphological characteristics of PS–SiO2 nanocomposites

- Load Frame Instruments

About the Author

Chalanda is the Thermal Analysis Specialist for DKSH Management overseeing the Asia Pacific region. In her PhD thesis, she developed and characterized polymer membranes for fuel-cell application. She has over 10 years of experience in Thermal Analysis Instruments and their applications. She also supports the thermal analyzer customers in South East Asia.

Chalanda Chulakham

Material Science

About the Author

Roman Ratayczak is the General Manager of Business Development at DKSH Technology, with over 26 years of expertise in management, sales, project leadership, and manufacturing across the automotive and machine tool sectors. A highly innovative professional, Roman brings a wealth of experience in leading teams and driving business success. He has spent over 13 years working in multicultural and global environments, particularly in Korea and Thailand, where his multilingual skills have enhanced his ability to navigate complex, cross-cultural business landscapes.

Roman Ratayczak

Precision Machinery & Semiconductor and Electronics

About the Author

Afzalur Alfan received his M.Sc in materials science & engineering from National University Malaysia. He has been with DKSH for 8 years and is now serving as Senior Manager for the Materials Science Team in Indonesia. He has experience in several scientific instrumentation techniques such as laser diffraction, dynamic light scattering, differential scanning calorimetry and rheology.

Afzalur Alfan

Material Science

About the Author

Carissa Lim is the Senior Application Specialist at DKSH Singapore, bringing over 18 years of diverse experience to her role. Her expertise spans project management, training coordination, scientific research, and quality assurance. Certified as a Food Safety Preventive Control Alliance (FSPCA) Preventive Controls Qualified Individual for Human Food, she also has expertise as an internal auditor for both Hazard Analysis Critical Control Point (HACCP) and Good Distribution Practice for Medical Devices (GDPMDS). Previously, Carissa spent more than 9 years in the food safety industry, where she leverages her knowledge in microbiology and food science education to assist food processors in developing and implementing effective food safety strategies and testing methods.

Carissa Lim

Food Science

About the Author

Cathleen Lin is the General Manager of Scientific Instrumentation at DKSH Business Unit Technology, China. With an extensive background in the instrumentation industry, she brings over 25 years of experience in sales and marketing, product management, and business development in China. She holds a Bachelor Degree in Applied Chemistry from Fudan university, and an MBA from East China University of Science and Technology (ECUST).

Cathleen Lin

Material Science