Advantages of Semi Quantitative Analysis (Omnian) in Alternative Fuels Testing Using EDXRF Epsilon 4

Author: Kristian Jude Borres, Application Specialist, DKSH Market Expansion Services

Introduction

A global trend in the cement industry has seen an increase in the adoption of alternative fuel sources such as Refuse-Derived Fuel (RDF), which enhance sustainability and reduce reliance on traditional fossil fuels. RDF is a highly variable product that is sourced from non-recyclable municipal, commercial, or industrial waste, which offers both economic and environmental benefits. However, its heterogeneous nature poses significant challenges for consistent process operations. Access to accurate and rapid elemental analysis while using non-traditional raw materials is crucial for maintaining clinker quality and kiln efficiency.

In this application note, we will explore the power of the Epsilon 4 benchtop Energy Dispersive X-ray fluorescence (XRF) spectrometer in conjunction with the Omnian software for standardless analysis at non-vacuum environment. Epsilon 4 can analyze elements from fluorine (F) to americium (Am) across various sample types, including solids and loose powders, without the need for extensive sample preparation. Employing close coupled optics with high surface area, solid state Silicon Drift Detectors, High linear count rates can be achieved with low-cost ownership.

Sample Preparation and Measurement

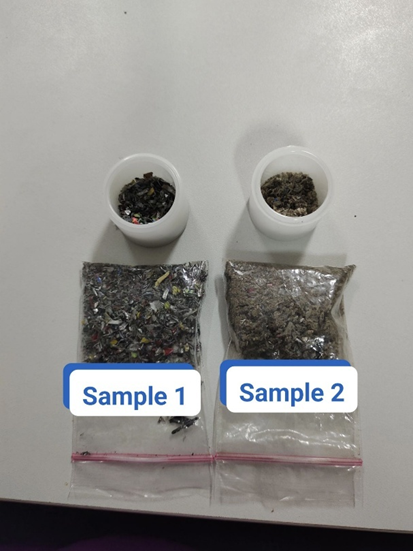

Two different Shredded RDF samples were placed directly into sample cups without any additional preparation. Measurements are conducted in an air medium using the Omnian application, which allows for rapid and reliable elemental analysis without the necessity for certified reference materials and calibrations. Inputting sample-specific details such as weight, height, and diameter facilitated more accurate quantification. The analysis yielded results within minutes, enabling efficient assessment of the sample’s elemental composition.

Existing Challenges in RDF Analysis

Analyzing RDF presents several challenges:

- Sample Heterogeneity: RDF’s varied composition requires representative sampling to ensure accurate determination of elemental percentages.

- Traditional Chemistry: Conventional wet chemical analysis is labor-intensive, time-consuming, and prone to human error, limiting its effectiveness for routine RDF analysis.

- Limited Elemental Scope: Wet methods often cannot detect all elements (currently limited to Chloride and Sulfur) of interest, particularly minor and trace oxides critical for process control.

Advantages of XRF Technology

Rapid Analysis: Obtain elemental composition results within minutes, facilitating timely decision-making.

- Minimal Sample Preparation: Direct analysis of shredded samples reduces preparation time and potential errors.

- Comprehensive Elemental Detection: Capable of detecting a broad range of elements, including major and minor oxides, essential for maintaining clinker quality.

- Standardless Quantification: Omnian software enables accurate analysis without the need for calibration standards, ideal for heterogeneous materials like RDF.

Results

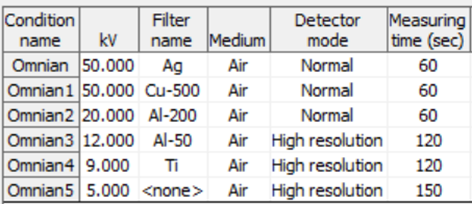

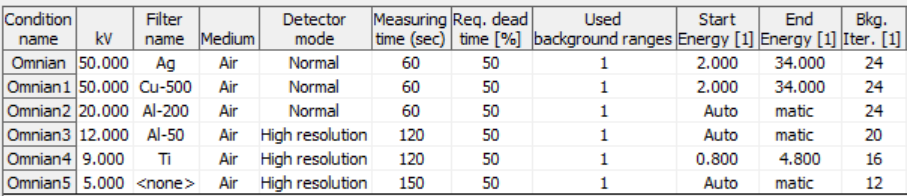

Two RDF samples are analyzed using Omnian Measurement using the following conditions:

The effect of material density on measurement accuracy was controlled by the use of ‘Processing Parameters’ that allow for the difference in sample weight, height and density to be incorporated into the calculation algorithm. In addition, we specified the characteristics of the Mylar film used to contain the powder—defining its thickness, density, and reported trace contaminants—so the Omnian software could apply proper absorption and background corrections.

We also modelled the presence of organic material in the sample matrix and used CO₂ as the balance compound, allowing the calculation of all remaining elements by mass while accounting for organic carbon content. This way, the software can reliably derive a complete elemental analysis.

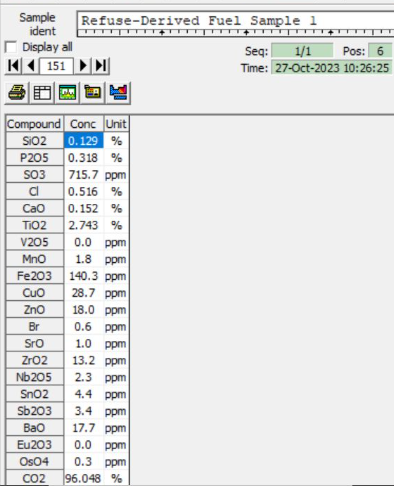

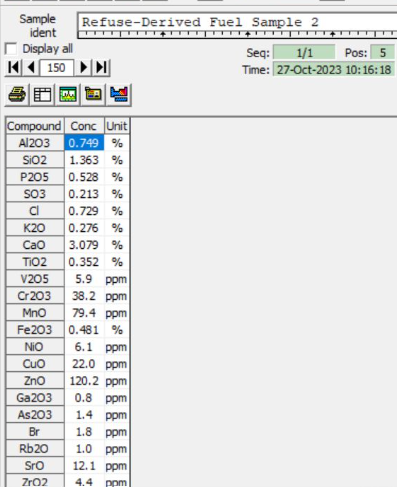

Below are the quantitative results for the two RDF test samples analyzed under these conditions.

In a typical cement‑industry alternative fuel testing, only sulfur (S) and chlorine (Cl) are routinely monitored using conventional wet analysis methods. With the expanded XRF results, customers can now also observe other metals present in their RDF samples—which may influence the pyro‑processing of clinker—and assess the potential environmental impact by tracking heavy metals beyond just S and Cl.

Conclusion

The integration of Epsilon 4 XRF technology with Omnian software provides a robust solution for the elemental analysis of RDF in the cement industry. This approach enhances analytical efficiency, accuracy, and supports the industry’s shift towards sustainable fuel alternatives.ng.

Related Products

About the Author

Kristian Jude Borres is a licensed Chemical Engineer and Chemical Technician with a degree in B.S. Chemical Engineering from Mapúa Institute of Technology. He brings nearly eight years of experience in the cement industry, where he specialized in material characterization and laboratory automation. At DKSH, Jude serves as the Application Specialist for Malvern Panalytical products, supporting customers across various industries. His expertise spans a range of analytical techniques, including X-ray fluorescence (XRF), X-ray diffraction (XRD), laser diffraction, and dynamic light scattering (DLS). He works closely with laboratories to help them optimize their testing processes through effective application of spectrometry and spectroscopy technologies.

Kristian Jude Borres

Material Characterization and Laboratory Automation